Design Capacity Tables for Structural Steel in PDF format are essential resources for structural engineers and designers. These tables provide comprehensive data on the load and stress capacities of various steel sections. They aid in efficient and safe structural designs‚ adhering to standards like AS 4100.

Design Capacity Tables are fundamental tools in structural engineering‚ particularly when working with steel. These tables offer pre-calculated load and stress capacities for various steel sections‚ simplifying the design process and ensuring structural integrity. They are typically presented in PDF format for easy access and portability.

These tables are based on established standards such as AS 4100‚ providing engineers with reliable data that complies with industry regulations. The tables eliminate the need for repetitive calculations‚ saving time and reducing the risk of errors. They are widely used by practitioners to determine the suitability of steel sections for specific applications.

The Design Capacity Tables are organized by section type‚ steel grade‚ and other relevant parameters. This allows engineers to quickly find the necessary information for their design. The tables often include detailed explanations of the assumptions and limitations used in their preparation‚ ensuring that they are used appropriately. They serve as a valuable reference for both experienced engineers and those new to structural steel design.

Furthermore‚ the tables are regularly updated to reflect changes in standards and the availability of new steel products. This ensures that engineers have access to the most current information. The PDF format allows for easy distribution and integration into design software‚ further enhancing their usability. Overall‚ Design Capacity Tables are indispensable resources for anyone involved in structural steel design.

Purpose of Design Capacity Tables

The primary purpose of Design Capacity Tables is to streamline the structural steel design process by providing readily available‚ pre-calculated capacities for various steel sections. These tables eliminate the need for engineers to perform complex calculations for each design scenario‚ saving significant time and effort. They ensure consistency and accuracy in design by adhering to established standards such as AS 4100.

These tables facilitate efficient selection of appropriate steel sections for specific load requirements. Engineers can quickly determine whether a particular section meets the necessary strength and stability criteria. This allows for optimized designs that minimize material usage and construction costs. The tables also promote safety by ensuring that structures are designed to withstand the intended loads with adequate factors of safety.

Design Capacity Tables serve as a valuable resource for both experienced engineers and those new to structural steel design. They provide a clear and concise overview of the load-carrying capabilities of different steel sections‚ aiding in understanding the behavior of steel structures. The tables are also essential for verifying the adequacy of existing structures and assessing their suitability for altered loading conditions.

Furthermore‚ these tables support standardization in design practices‚ ensuring that all engineers are using the same basis for their calculations. This facilitates communication and collaboration among design teams and promotes consistency in construction quality. Ultimately‚ the purpose of Design Capacity Tables is to enhance the efficiency‚ safety‚ and reliability of structural steel design.

Standards and Codes (e.g.‚ AS 4100)

Design Capacity Tables for structural steel are intrinsically linked to relevant standards and codes‚ most notably AS 4100 (Steel Structures Standard) in Australia. These standards provide the fundamental principles‚ requirements‚ and guidelines for the design‚ fabrication‚ and erection of steel structures. The Design Capacity Tables are developed to align with these standards‚ ensuring that designs based on the tables comply with the code requirements.

AS 4100‚ for example‚ specifies the limit states design approach‚ which considers both strength and serviceability criteria. The Design Capacity Tables provide pre-calculated capacities based on these limit states‚ simplifying the design process. The tables incorporate the appropriate capacity factors (φ) as specified in AS 4100‚ ensuring that the designs achieve the required level of safety.

Compliance with standards and codes is paramount in structural engineering to ensure the safety and durability of structures. Design Capacity Tables‚ by being aligned with these standards‚ help engineers to meet their professional obligations and legal requirements. They also facilitate the approval process by regulatory authorities‚ as designs based on the tables are readily verifiable against the code requirements.

Furthermore‚ standards and codes are continuously updated to reflect advancements in knowledge and technology. Design Capacity Tables are revised periodically to remain consistent with the latest editions of the relevant standards‚ ensuring that engineers are using the most current and accurate information.

Availability of Design Capacity Tables (PDF Format)

Design Capacity Tables for structural steel are widely accessible in PDF format‚ making them a convenient resource for engineers and designers. The Australian Steel Institute (ASI) is a primary source for these tables‚ offering them for download on their website. These PDF documents are typically organized into volumes‚ such as Volume 1 for open sections and Volume 2 for hollow sections.

The PDF format allows for easy distribution and viewing across various devices‚ ensuring that engineers can access the data they need regardless of their location. The tables are often searchable‚ enabling users to quickly locate specific steel sections and their corresponding capacities. Additionally‚ the PDF format preserves the formatting and layout of the tables‚ ensuring that the information is presented clearly and accurately.

Many universities and technical institutions also provide access to Design Capacity Tables in PDF format through their libraries or online resources. This ensures that students and researchers have access to the data they need for their studies and projects. Furthermore‚ some steel manufacturers may offer their own versions of the Design Capacity Tables‚ tailored to their specific products.

It is important to ensure that the PDF documents are obtained from reputable sources‚ such as the ASI or established steel manufacturers‚ to guarantee the accuracy and reliability of the data. Users should also verify that the tables are consistent with the relevant standards and codes‚ such as AS 4100.

Open Sections (Volume 1)

Volume 1 of the Design Capacity Tables for Structural Steel typically focuses on open sections‚ which are commonly used in a wide range of structural applications. These sections include universal beams (UB)‚ universal columns (UC)‚ wide flange beams (WB)‚ channels (PFC)‚ and angles. The tables in Volume 1 provide detailed information on the dimensions‚ properties‚ and design capacities of these open sections.

The design capacities are calculated based on relevant standards and codes‚ such as AS 4100‚ and take into account various limit states‚ including bending‚ shear‚ and axial compression; The tables also provide information on the section’s resistance to buckling and other forms of instability. This information is essential for engineers to ensure that the selected steel sections can safely withstand the applied loads and stresses.

Volume 1 also includes information on the steel grades that are commonly used for open sections‚ such as Grade 300 and Grade 400. The tables specify the yield strength and tensile strength of these steel grades‚ which are important parameters for calculating the design capacities. Additionally‚ Volume 1 may include information on the manufacturing process of open sections‚ such as hot-rolling.

The tables in Volume 1 are typically organized by section type and size‚ making it easy for engineers to find the information they need. The tables may also include diagrams of the section shapes‚ along with the dimensions and properties. This information is essential for accurate structural design and analysis.

Hollow Sections (Volume 2)

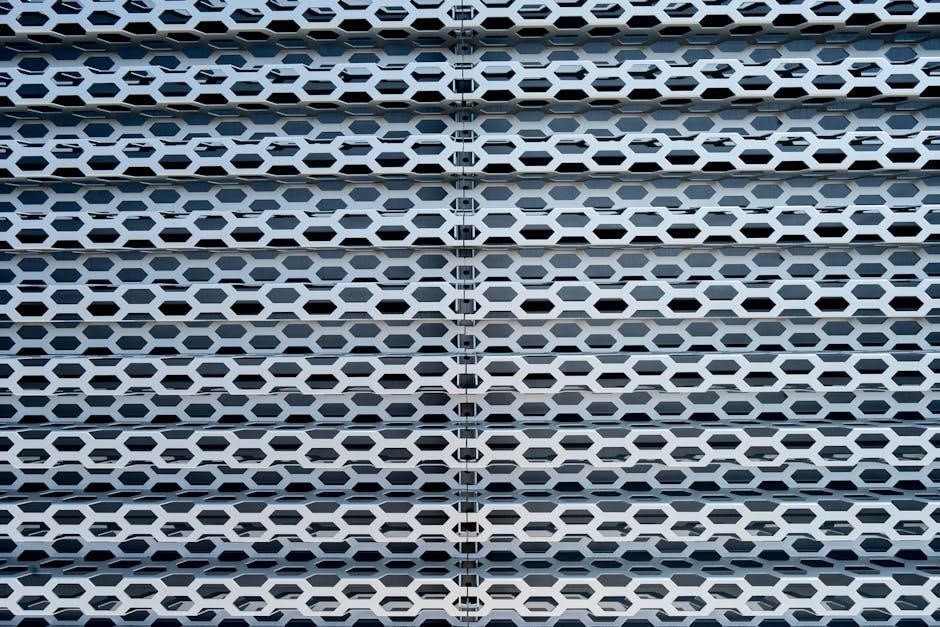

Volume 2 of the Design Capacity Tables for Structural Steel is dedicated to hollow sections‚ which offer unique advantages in structural design due to their high strength-to-weight ratio and resistance to buckling. This volume typically covers a range of hollow section types‚ including circular hollow sections (CHS)‚ square hollow sections (SHS)‚ and rectangular hollow sections (RHS). These sections are commonly used in columns‚ beams‚ and bracing members.

The tables in Volume 2 provide detailed information on the dimensions‚ properties‚ and design capacities of these hollow sections. The design capacities are calculated based on relevant standards and codes‚ such as AS 4100‚ and take into account various limit states‚ including bending‚ shear‚ axial compression‚ and local buckling. Volume 2 includes data related to section properties that are unique to hollow sections.

The tables also provide information on the steel grades that are commonly used for hollow sections. The specified yield strength and tensile strength of these steel grades are important parameters for calculating the design capacities. Volume 2 may include information on the manufacturing process of hollow sections‚ such as welding and cold-forming.

The information provided in Volume 2 is essential for engineers to design safe and efficient structures using hollow sections. The tables are typically organized by section type and size‚ making it easy to find the required information. The tables may also include diagrams of the section shapes‚ along with the dimensions and properties‚ ensuring accuracy in structural design and analysis.

Connection Design (Volume 4)

Volume 4 of the Design Capacity Tables for Structural Steel focuses on connection design‚ a critical aspect of structural engineering. Connections are the joints that transfer loads between structural members‚ and their design is crucial for the overall safety and stability of a steel structure. This volume typically covers a wide range of connection types‚ including bolted connections‚ welded connections‚ and pinned connections.

The tables in Volume 4 provide detailed information on the design capacities of these connections. The design capacities are calculated based on relevant standards and codes‚ such as AS 4100‚ and take into account various failure modes‚ including bolt shear‚ weld fracture‚ and bearing failure. The tables may also include information on the detailing requirements for connections‚ such as bolt spacing‚ edge distances‚ and weld sizes.

Volume 4 includes data on different types of bolts and welds‚ along with their respective strength properties. Information on the steel grades used in connection design is also provided‚ ensuring compatibility between the connection elements and the structural members they connect. The tables may also include guidelines on the selection of appropriate connection types for different loading conditions and structural configurations.

The information provided in Volume 4 is essential for engineers to design connections that can safely and reliably transfer loads between structural members. The tables are typically organized by connection type and configuration‚ making it easy to find the required information. The tables may also include diagrams of the connection details‚ along with the dimensions and properties‚ ensuring accuracy in connection design and analysis.

Steel Grades and Specifications

Understanding steel grades and specifications is fundamental when utilizing design capacity tables for structural steel. These tables are intrinsically linked to the mechanical properties of specific steel grades. The grades define the yield strength‚ tensile strength‚ and ductility‚ all vital for accurate structural design. Specifications outline the manufacturing processes‚ chemical composition‚ and testing requirements‚ ensuring consistent quality and performance.

Common steel grades referenced include Grade 300 and Grade 400‚ compliant with standards like AS/NZS 3679.1 and AS/NZS 3679.2. These standards dictate the acceptable limits for various elements‚ such as carbon‚ manganese‚ and silicon‚ which influence steel weldability and corrosion resistance. The design capacity tables provide values based on these specific steel grades‚ allowing engineers to select appropriate sections.

The tables consider the “Ry” factor‚ which is derived from the characteristic values and specified parameters detailed in sections 5 to 9 of AS 4100. The steel’s yield strength directly impacts the moment and axial load capacities listed in the tables‚ enabling accurate assessment of structural member strength. Additionally‚ steel specifications ensure the material’s suitability for different applications‚ such as high-stress environments or fire-resistant structures.

Designers must carefully consider the steel grade and specification to guarantee the structure meets the required safety and performance criteria. Mismatched grades can lead to underestimation of load-bearing capacity or premature failure. Therefore‚ a thorough understanding of steel properties and their influence on design parameters is paramount.

Applications of Structural Steel

Structural steel finds extensive use across diverse engineering applications‚ relying heavily on design capacity tables for efficient and safe implementation. These tables are critical in designing steel frames for buildings‚ providing load-bearing capacities and ensuring structural integrity under various loads. In bridge construction‚ structural steel‚ guided by these tables‚ enables the creation of robust and durable spans capable of withstanding heavy traffic and environmental stresses.

Industrial structures‚ such as warehouses and factories‚ also benefit significantly from the use of structural steel‚ with design capacity tables dictating the dimensions and configurations needed for optimal performance. The tables are instrumental in designing columns‚ beams‚ and trusses that support heavy machinery and equipment. Moreover‚ structural steel plays a vital role in specialized structures like offshore platforms and wind turbine towers‚ where strength and stability are paramount.

In residential construction‚ steel is increasingly used for framing‚ offering advantages such as durability‚ resistance to pests‚ and fire resistance. Design capacity tables ensure that steel members meet the required load-bearing requirements for homes and apartments. The tables also guide the design of temporary structures‚ such as scaffolding and formwork‚ ensuring safety during construction.

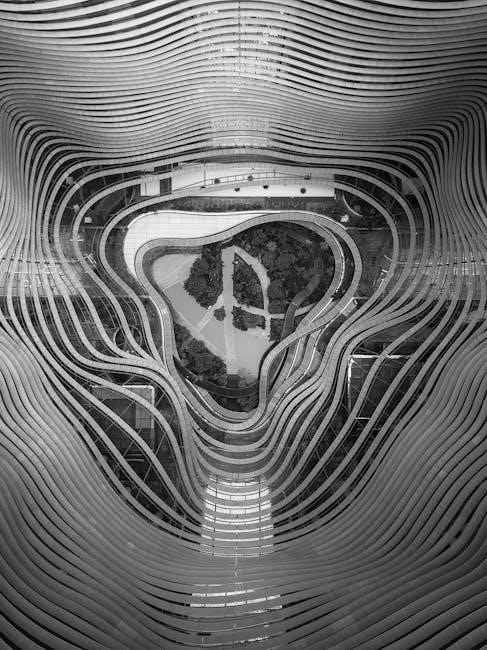

Finally‚ structural steel and its design tables are indispensable in creating aesthetically pleasing architectural designs‚ allowing for long spans and unique structural forms while maintaining safety and structural soundness. The versatility and reliability of structural steel‚ coupled with precise design using these tables‚ make it a favored material in modern construction and engineering.

Using Steel Section Properties Tables

Steel section properties tables are essential tools for structural engineers‚ providing critical data needed for designing safe and efficient steel structures. These tables offer detailed information on geometric properties such as area‚ moment of inertia‚ section modulus‚ and radius of gyration for various standard steel sections like I-beams‚ channels‚ and hollow sections. Understanding and correctly using these properties is crucial for accurate structural analysis and design.

When using these tables‚ engineers can determine a section’s resistance to bending‚ buckling‚ and shear forces. The moment of inertia‚ for example‚ indicates a section’s resistance to bending‚ while the section modulus relates to its bending stress capacity. The radius of gyration is vital for assessing a member’s susceptibility to buckling under compressive loads.

Selecting the appropriate steel section for a given application involves comparing the required strength and stiffness with the properties listed in the tables. Engineers must consider factors such as applied loads‚ span lengths‚ and support conditions. These tables also help in optimizing designs by choosing the most efficient section that meets the design requirements‚ minimizing material usage and cost.

Furthermore‚ steel section properties tables are used in conjunction with design codes and standards like AS 4100 to verify the adequacy of selected sections. These tables facilitate calculations for load combinations‚ stress checks‚ and deflection limits‚ ensuring the structural integrity and safety of steel structures. Therefore‚ a thorough understanding and proper application of steel section properties tables are fundamental for successful structural steel design.

Software for Steel Structure Design

Specialized software plays a crucial role in modern steel structure design‚ streamlining complex calculations and analyses. These software tools integrate steel section properties‚ design codes such as AS 4100‚ and advanced analysis capabilities‚ enhancing accuracy and efficiency. They enable engineers to model structures‚ apply loads‚ and simulate behavior under various conditions‚ predicting stresses‚ deflections‚ and stability.

Software solutions often include extensive libraries of steel sections‚ allowing designers to easily select and analyze different profiles. They can perform finite element analysis (FEA) to assess complex structural behavior‚ considering factors like material properties‚ connection types‚ and boundary conditions. Automated design checks ensure compliance with relevant standards‚ reducing errors and improving safety.

Furthermore‚ software facilitates optimization by evaluating different design alternatives and identifying the most efficient solutions. It generates detailed reports‚ including material takeoffs‚ connection details‚ and design calculations‚ aiding in documentation and construction. Collaboration is enhanced through shared models and data‚ improving communication between engineers‚ fabricators‚ and contractors.

Popular software packages include those offering capabilities for both analysis and design‚ often incorporating BIM (Building Information Modeling) integration for seamless workflow. These tools help manage complex projects‚ ensuring that steel structures are designed to meet performance requirements while optimizing material usage and minimizing costs. Consequently‚ software is indispensable for steel structure design‚ promoting innovation and efficiency in the construction industry.